MechForm specializes in manufacturing of Rotary Vaccum Dryer(RVD). With over two decades of experience RVD are uniquely designed equipment. It incorporates unique technology of heating under vaccum to prevent degradation of raw material. Here raw material is mixed by rotating slowly and dried by applying heat. The raw material is under vacuum & hence the drop of steam pressure makes the moisture(solvent)at the surface of raw material to be saturated which later evaporates at relatively lower temperatures

Application

Double cone rotary vacuum dryer is applicable for drying and mixing powdery and granular materials in the pharmaceutical, food, chemical, dye and other industries. It is especially suitable for the following materials:

- Thermosensitive materials that cannot withstand high temperature

- Easily oxidized and dangerous materials

- Materials whose solvent should be recovered and materials of poisonous gas

- Materials required low residual volatile content

- Materials with requirements on crystal shape

Additional Features

- This rotary vacuum dryer has advanced design, simple internal structure, convenient to clean and easy to handle.

- Condenser and recycling tank can be equipped for recovering organic solvent.

- Our double cone vacuum dryer has three types of heat source, including steam, hot water and conduction oil.

- Hydraulic-operated butterfly discharge valve

- Available in various materials - SS316/304, MS, MS-SS Clad, Hastelloy-C22, C276.

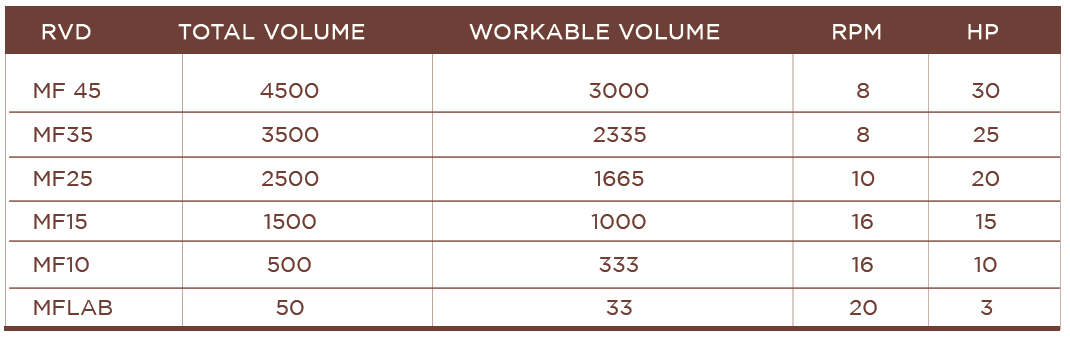

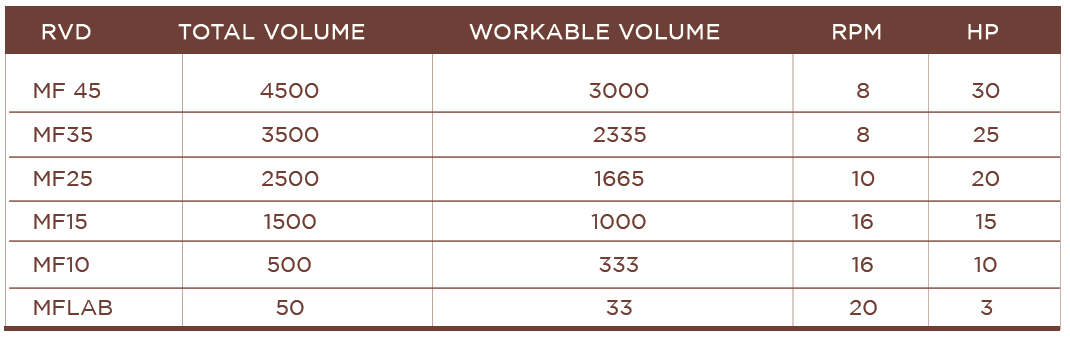

- Also available in custom sizes from lab model to 8OOO L volumetriccapacity.