FLUSHERS OR PREMIXERS

Flushers are Sigma Kneaders designed for highly viscous application and considering severe torque requirements. We manufacture specially engineered Flushers for our esteemed clients in various ranges & specifications.The process of Pigment flushes involves press cake being fluidized using a hydrophobic organic medium and then fed into Flushers. Flushing helps keeping pigment particles non agglomerated and easier to use in making inks and pigments.It flushes the pigment particles from the water phase to the organic medium phase and displace the water as a separate aqueous phase. The displaced water is separated and the dispersion of the pigment in the varnish can be used as a pigment paste in preparing an ink or paint. The flusher has a provision for heating with vacuum preventing product damage due to heating. Flushing is also used to increase the pigment concentration in a standard dry color concentrate.

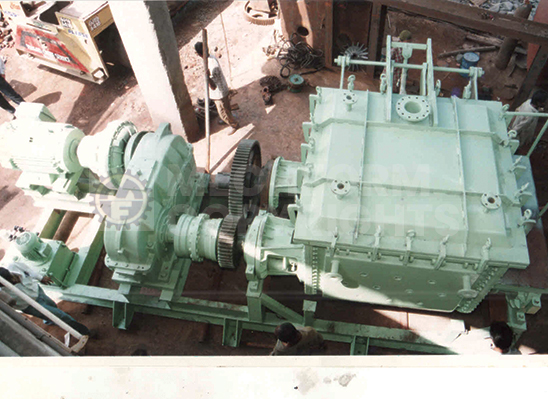

CONSTRUCTION

We specialize in various range of Flushers from lab size to 6000 L for preparing pigment flushwith a drive system comprising of VFD/fluid coupling, helical reduction gearbox, a gear coupling and heavy-duty helical gears driving twin pair of Sigma Blades. This mixer is jacketed for heating and cooling operation and suitable for vacuum operation. The material is discharged through the tilting of the mixing container. These mixers are offered in grades of Stainless Steel, Alloy Steel, and Carbon Steel. The mixers can be offered for container tilting discharge, bottom discharge, or discharge through a screw.